A furnace pressure switch is an essential safety device that monitors proper exhaust gas venting. Common problems include torn diaphragms, blocked hoses, and electrical contact failures. When issues arise, the switch prevents furnace operation to avoid hazardous conditions like carbon monoxide buildup.

Basic troubleshooting involves inspecting hoses for blockages, checking electrical connections, and testing switch functionality with a multimeter. While simple problems like loose connections can be DIY fixes, complex issues require professional attention. Regular maintenance of pressure switches and associated components helps prevent unexpected furnace shutdowns. The following guide explores proven solutions for pressure switch diagnosis and repair.

Key Takeaways for Resolving Furnace Pressure Switch Issues

- Check pressure switch hoses for blockages, cracks, or loose connections that can prevent proper pressure detection and switch operation.

- Test electrical continuity using a multimeter across switch terminals when proper vacuum conditions are present.

- Inspect the draft inducer motor for proper operation, as its failure can prevent adequate pressure for switch activation.

- Look for damaged or torn diaphragms inside the pressure switch that could compromise its ability to sense pressure changes.

- Clean debris from switch housing and verify proper mounting position to ensure accurate pressure readings.

How Does a Furnace Pressure Switch Work?

The furnace pressure switch serves as the primary safety guardian of your heating system by monitoring pressure conditions through a flexible diaphragm mechanism. When operating properly, this indispensable component closes an electrical circuit only when the correct negative pressure is detected, permitting the furnace to begin its heating cycle.

While the pressure switch’s design is relatively straightforward, it can experience various issues including damaged diaphragms, electrical failures, and blocked hoses that compromise its crucial safety function. Regular inspection of pressure switch hoses and proper maintenance can help prevent common operational issues that lead to furnace shutdowns.

Key Components and Their Functions

Modern furnace pressure switches consist of critical components working together to monitor and control safe furnace operation.

The main component is a flexible diaphragm that responds to pressure changes within the system. When proper pressure is detected, the diaphragm moves, causing electrical contacts to close, and allowing the furnace to operate.

If unsafe conditions occur, the switch prevents furnace ignition.

The Safety Role of Pressure Switches in Furnace Operation

Within residential heating systems, pressure switches serve as critical safety gatekeepers by monitoring exhaust gas flow and maintaining dangerous operating conditions.

Working alongside the draft inducer motor, this safety switch safeguards the proper venting of combustion gases. If the combustion switch detects inadequate pressure levels, it immediately shuts down the furnace to prevent carbon monoxide buildup and other hazards.

Common Pressure Switch Failures Explained

Pressure switches commonly fail due to several predictable vulnerabilities in their components and operating conditions. The air pressure sensor and vacuum switch mechanisms can deteriorate over time, leading to system failures.

- Torn or damaged diaphragm preventing proper pressure detection

- Corroded electrical contacts disrupting switch signals

- Blocked or cracked pressure-sensing tubes

- Debris accumulation within the switch housing affects the operation

Step-by-Step Guide to Diagnosing Furnace Pressure Switch Problems

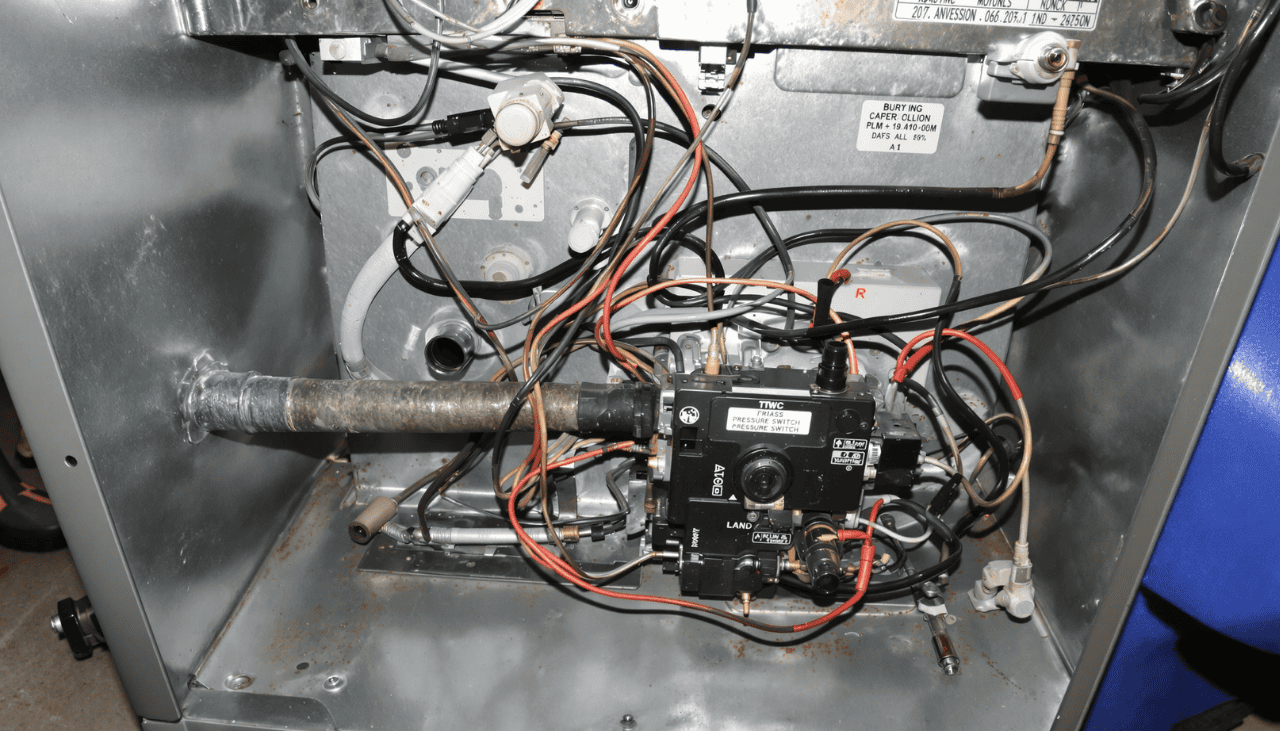

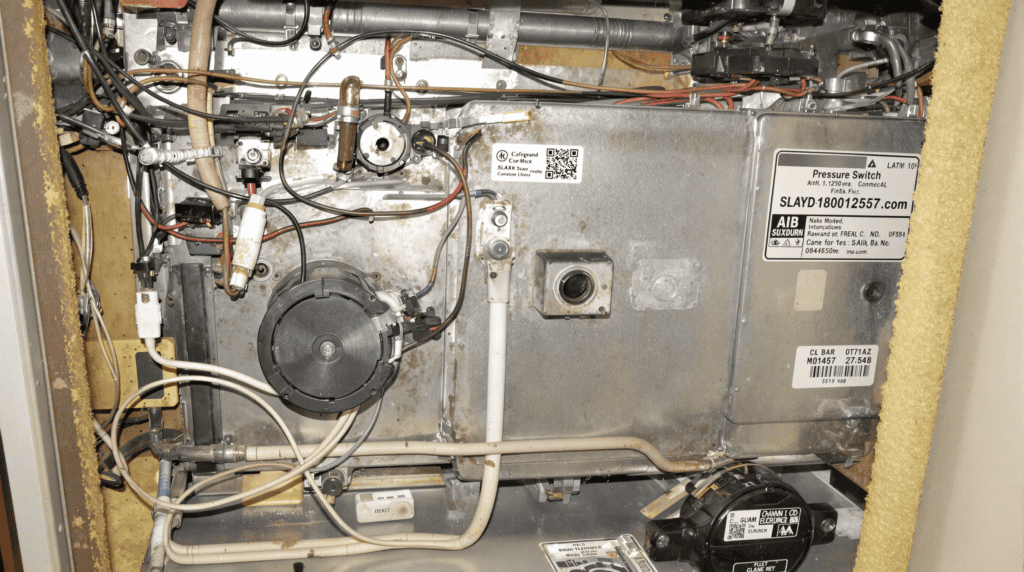

When troubleshooting a furnace pressure switch, having the right diagnostic tools such as a multimeter, manometer, and basic hand tools is crucial for accurate testing. A systematic approach to testing begins with inspecting the physical components for obvious damage, followed by electrical testing to verify switch operation and pressure measurements to confirm proper functionality. Understanding how to interpret test results helps determine whether simple maintenance will resolve the issue or if component replacement is necessary. Proper motor lubrication and cleaning should be checked during pressure switch diagnostics, as insufficient maintenance can affect overall system performance.

Essential Tools and Equipment for Pressure Switch Diagnostics

Proper diagnosis of furnace pressure switch issues requires several critical tools and testing equipment. Having the right instruments guarantees accurate troubleshooting and safe maintenance procedures.

- Digital multimeter for testing electrical continuity and voltage

- Manometer or pressure tester to measure switch activation points

- Basic hand tools including screwdrivers and pliers

- Vacuum cleaner to remove debris around switch components

How to Test a Furnace Pressure Switch: A Step-by-Step Process

A systematic approach to testing furnace pressure switches helps identify the root cause of operational issues while ensuring safety throughout the diagnostic process.

Begin by inspecting the vacuum hose connections, then use a diagnostic tool to measure the switch’s continuity. Finally, confirm the voltage rating matches manufacturer specifications and check for proper pressure differential across the switch terminals.

Understanding Test Results for Furnace Pressure Switches

Testing a furnace pressure switch generates specific patterns and readings that indicate the system’s operational status. When using a vacuum gauge and monitoring the control board signals, proper fault detection involves analyzing key measurements.

The switch remains open with readings below -0.5″ W.C. indicating insufficient draft.

Normal operation shows consistent readings between -0.8″ to -1.2″ W.C.

Fluctuating readings suggest damaged diaphragm or blocked ports.

Erratic control board signals point to electrical connection issues.

Troubleshooting Common Pressure Switch Problems in Furnaces

Several key issues can cause furnace pressure switch malfunctions, including physical damage to components like the diaphragm, electrical problems with voltage or connections, and environmental challenges such as excessive humidity or debris accumulation.

Physical damage often results from normal wear and tear or improper handling, while electrical malfunctions typically stem from loose wiring or voltage irregularities.

Environmental factors pose an ongoing threat to pressure switch operation, as dust, dirt, and moisture can gradually compromise the switch’s ability to function properly. A faulty pressure switch may trigger ignition problems that create loud banging or popping sounds during furnace startup.

Physical Damage and Component Wear

Physical damage to pressure switch components represents one of the most common causes of furnace malfunction. Failed diaphragms, stuck contacts, and cracked hoses can prevent proper pressure detection and system operation.

- Torn or brittle diaphragms unable to flex with pressure changes

- Contact points corroded or welded together from electrical arcing

- Cracked or split vacuum hoses cause pressure loss

- Warped mounting brackets lead to misaligned components

Electrical Issues Affecting Pressure Switch Performance

While mechanical issues are often visible, electrical malfunctions in furnace pressure switches can be more challenging to diagnose and resolve.

Common signs of electrical failure include switches failing to close properly or the furnace entering lockout mode. Professional contact testing with a multimeter can identify voltage problems, loose connections, and faulty wiring that prevent proper switch operation.

Environmental Factors That Impact Pressure Switch Operation

The environment where a furnace pressure switch is installed can greatly affect how well it works and how long it lasts. For instance, if the area is too damp, it can lead to rust and damage to the sensors. Dust and debris can build up and block the ports, preventing the switch from functioning properly.

Temperature changes can throw off its pressure readings, making it less reliable. Finally, exposure to airborne chemicals can harm the parts of the switch, causing it to wear out faster. Taking care of these environmental factors is key to keeping the furnace pressure switch in good shape.

Repairing and Replacing Furnace Pressure Switches

When faced with a malfunctioning furnace pressure switch, homeowners must carefully assess whether the issue requires simple maintenance or professional intervention.

Minor problems like loose hoses or debris buildup can often be addressed through basic DIY cleaning and reconnection, while more complex issues involving electrical components or damaged diaphragms should be handled by qualified HVAC technicians.

The replacement of a pressure switch demands proper safety protocols, including shutting off power to the furnace and ensuring the new component matches manufacturer specifications precisely.

Maintain 30-inch clearance between the furnace and walls to ensure proper access during pressure switch repairs and replacements.

DIY Tips for Fixing Furnace Pressure Switch Problems

A homeowner’s ability to repair furnace pressure switch issues safely depends on their technical expertise and the nature of the problem.

Simple maintenance tasks can often resolve basic issues when properly executed.

- Inspect and clean debris from the flue pipe to guarantee proper airflow

- Replace cracked or damaged hoses with manufacturer-approved parts

- Clean pressure switch ports using compressed air to eliminate blockages

- Check all connections are secure and properly seated

When to Call a Professional HVAC Technician

Professional furnace technicians offer specialized expertise and equipment necessary for complex pressure switch repairs that extend beyond basic maintenance. They can accurately diagnose issues, verify operating parameters, and guarantee proper mounting bracket installation.

Licensed technicians also have access to manufacturer-specific parts and diagnostic tools, making them critical for intricate repairs that require precise calibration and testing.

Step-by-Step Furnace Pressure Switch Replacement Guide

Replacing a faulty furnace pressure switch is a task that requires careful attention to safety and precision. First, make sure to disconnect the power to the furnace to avoid any accidents. Then, carefully remove the wire connectors from the old switch, making sure to label them for easy reconnection later.

Next, detach the pressure tubes from the existing switch, again noting where each one connects. Once that’s done, mount the new pressure switch exactly in the same position as the old unit.

After that, reconnect the tubes and wires according to the labels you made earlier. Finally, turn the power back on and test the operation to ensure everything is working smoothly. Following these steps will help ensure your furnace operates safely and efficiently.

Optimizing Furnace Performance with Pressure Switch Maintenance

Regular preventive maintenance of your furnace’s pressure switch system can help avoid costly breakdowns and guarantee safe operation throughout the heating season. Monitoring your furnace’s performance through careful observation of heating patterns and unusual sounds provides early warning signs of potential pressure switch issues.

Upgrading to modern electronic pressure switches offers improved reliability and better resistance to environmental factors compared to older mechanical models. Implementing proper duct sealing techniques can prevent up to 20% loss of heated air and improve overall system efficiency.

Preventative Maintenance Tips for Furnace Pressure Switches

Effective maintenance of your furnace’s pressure switch system requires a systematic approach to prevent potential failures. Regular preventive maintenance steps should include monitoring the draft sensor and inspecting tubing connections quarterly.

- Clean pressure switch contacts and housing with compressed air

- Test switch operation during heating season shifts

- Verify all tubing connections are secure and free from damage

- Inspect draft sensor readings during annual maintenance checks

How to Monitor Furnace Pressure Switch Performance

Strategic monitoring of your furnace’s performance indicators can help identify pressure switch problems before they lead to system failure. Watch for delayed response time between thermostat adjustments and furnace activation, unusual cycling before reaching the temperature limit, and inconsistent activation point patterns.

Regular observation of these behaviours allows homeowners to address potential pressure switch issues promptly, preventing costly breakdowns.

Upgrade Options for Better Furnace Efficiency

Modernizing your furnace’s pressure switch system can substantially enhance both safety and efficiency. When upgrading from single-stage to two-stage or variable-speed systems, consider these improvements:

- Advanced electronic pressure monitoring with digital displays

- Self-diagnostic capabilities that alert homeowners to potential issues

- Multi-stage pressure switches that match modern furnace capabilities

- Integrated smart controls for remote monitoring and adjustment

These upgrades offer precise pressure regulation and enhanced protection against system failures.

Conclusion: Ensuring Furnace Safety and Efficiency

Proper maintenance and troubleshooting of furnace pressure switches remain critical for safe heating system operation. Through systematic diagnosis, regular inspection, and timely repairs, system reliability can be optimized while preventing hazardous conditions. Understanding switch functionality, following proper testing protocols, and implementing preventive maintenance strategies guarantees long-term furnace performance. When addressed promptly, pressure switch issues pose minimal risk to home heating safety and efficiency.