Your furnace’s frequent shutoffs can stem from various issues, including thermostat problems, airflow restrictions, faulty flame sensors, or fuel-related concerns. If you’re wondering “why does my furnace keep turning off?”, start by checking your thermostat settings and batteries. Clean or replace air filters and ensure vents aren’t blocked. Inspect the flame sensor for dirt or damage.

If these steps don’t help, you might have mechanical or electrical issues requiring professional attention. Be alert for signs of gas leaks or carbon monoxide, such as headaches or sooty stains near the furnace.

Regular maintenance can prevent many shutoff problems. For a deeper understanding of your furnace’s behaviour and more troubleshooting tips, continue exploring.

Key Takeaways

- Check for thermostat issues, including miscalibration, dead batteries, or incorrect settings.

- Inspect and clean or replace dirty air filters to ensure proper airflow.

- Clean or replace faulty flame sensors and check the ignition system for proper functioning.

- Examine electrical connections, circuit breakers, and control boards for malfunctions.

- Verify proper gas pressure, burner condition, and venting for efficient combustion and safe operation.

Common Causes of Frequent Furnace Shutoffs

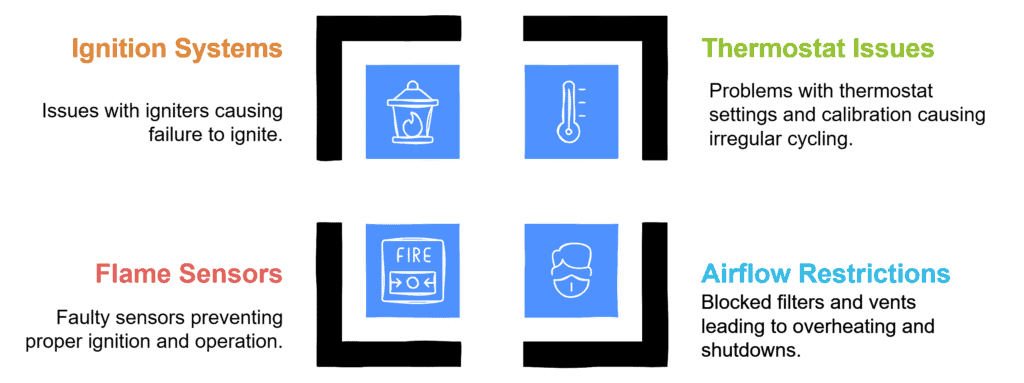

If your furnace keeps turning itself off, you’re likely facing one of several common issues. Your thermostat might be malfunctioning or miscalibrated, causing irregular cycling.

Alternatively, airflow restrictions from dirty filters or faulty flame sensors could be triggering safety shutdowns. A stuck pressure switch can also cause frequent shutoffs, often due to clogged hoses or improper venting.

Thermostat Issues and Miscalibrations

Your thermostat serves as the brain of your heating system, and when it malfunctions, your furnace can experience frequent shutoffs. Thermostat short cycling is a common issue that can lead to furnace short cycling.

Miscalibration, incorrect settings, or dead batteries can cause temperature inconsistency, leading to short cycling. Check your thermostat’s control system to diagnose these issues. Ensure it’s level, clean, and properly programmed. Replace batteries if needed.

If problems persist, consider calling a professional to recalibrate or replace your thermostat.

Airflow Restrictions and Filter Problems

Airflow restrictions and filter problems can lead to frequent furnace shutoffs, throwing a wrench in your home’s heating system. Dirty air filters and clogged blower wheels reduce airflow, causing the heat exchanger to overheat.

Blocked vents limit heat transfer, triggering shutdowns. These issues can make your furnace cycle on and off. Regular furnace maintenance, including changing air filters, is essential to prevent overheating and ensure proper operation.

Faulty Flame Sensors and Ignition Systems

Among the common culprits of frequent furnace shutoffs, faulty flame sensors and ignition systems top the list. Your heating system may struggle to ignite or stay lit due to these issues. Here’s a quick guide to help you identify the problem:

| Component | Symptom | Possible Cause | Solution |

|---|---|---|---|

| Flame Sensor | Furnace shuts off quickly | Dirty or faulty sensor | Clean or replace |

| Ignition System | No ignition | Worn-out igniter | Replace igniter |

| Gas Supply | Intermittent flame | Low gas pressure | Check gas valve |

| Combustion Chamber | Poor combustion | Debris buildup | Clean chamber |

Mechanical and Electrical Troubleshooting

When tackling mechanical and electrical issues with your furnace, start by checking the limit switches for proper function. The furnace limit switch plays a vital role in preventing overheating and ensuring safe operation. Inspect for visible damage or debris on the switch and verify its calibration.

Next, assess your blower motor’s performance to ensure it’s operating efficiently. Don’t forget to inspect circuit breakers and electrical connections, as faulty wiring can often cause unexpected shutoff.

Inspecting and Testing Limit Switches

Limit switches play a critical role in your furnace’s safety and operation. They protect against overheating and ensure proper airflow. During your safety inspection, check for a faulty limit switch, which can cause frequent shutoffs. Use your furnace’s self-diagnostics to identify issues. Look for tripped circuit breakers or faulty wiring in your HVAC system.

| Common Limit Switch Issues | Possible Causes | Solutions |

|---|---|---|

| Frequent shutoffs | Dirty filter | Replace filter |

| Overheating | Blocked vents | Clear vents |

| No heat | Faulty switch | Replace switch |

| Short cycling | Incorrect settings | Adjust settings |

Evaluating Blower Motor Performance

The blower motor is another key component that can cause furnace issues. A malfunctioning blower motor can lead to inconsistent heating. Check for worn-out bearings or a dirty blower wheel. Listen for unusual noises and ensure the motor runs smoothly.

Variable-speed and multi-speed motors require specific testing. Measure the airflow in cubic feet per minute to verify if the air handler is performing consistently. Replace the motor if it’s faulty.

Checking Circuit Breakers and Electrical Connections

Electrical issues can often lie at the heart of furnace problems. Check your circuit breakers and look for any tripped switches. Inspect the furnace’s electrical connections for loose or damaged wires.

A blown fuse or power supply issue can cause your heating system to shut off unexpectedly. Don’t forget to examine the control board for signs of malfunction. If you’re unsure, call a professional for safe troubleshooting.

Fuel and Combustion-Related Problems

When troubleshooting fuel and combustion problems in your furnace, start by checking the gas pressure and supply. Gas valve functionality is vital for proper gas flow and ignition.

If you notice clicking noises or a failure to ignite, it may indicate a malfunctioning gas valve. You’ll need to examine the burner condition and cleanliness, as dirty burners can cause inefficient combustion. Don’t forget to verify proper venting and exhaust, ensuring that harmful gases are safely removed from your home.

Assessing Gas Pressure and Supply

Proper gas pressure and supply are essential for your furnace to function efficiently and safely. Low gas pressure can lead to incomplete combustion and safety hazards.

Check for clogged gas lines or an empty fuel tank if you’re using propane. Natural gas users should inspect for blockages or leaks. Faulty pressure switches may need calibration.

Have a professional HVAC technician regularly assess your gas pressure and clean any contaminated fuel to prevent issues.

Examining Burner Condition and Cleanliness

Dirty or damaged burners can cause a multitude of furnace problems. They lead to ignition lockout, tripped flame rollout switches, and increased carbon monoxide production.

Clean burners are pivotal for efficient operation, especially in high-efficiency furnaces. Regular maintenance reduces fuel consumption and improves heat output.

Check your burners for debris, corrosion, or misalignment. If you’re unsure, call a professional to inspect and clean them safely.

Verifying Proper Venting and Exhaust

A well-functioning exhaust system is critical for your furnace’s safety and efficiency. Your heater’s flue and vents must be clear for proper operation. Blocked vents can cause your boiler or HVAC unit to shut down.

Check for:

- Obstructed exhaust flue

- Leaky ductwork

- Faulty draft inducer

- Malfunctioning pressure switch

- Debris in vents

Regular inspections ensure your furnace vents combustion gases safely. Ignoring these issues can lead to dangerous carbon monoxide buildup and system failures.

Safety Concerns and When to Call a Professional

When it comes to furnace safety, you’ll need to be aware of potential carbon monoxide leaks and overheating issues. These problems can pose serious risks to your health and home.

Carbon monoxide monitors should be installed 5 feet above the ground and regularly maintained to ensure early detection of this dangerous gas. While some furnace repairs are suitable for DIY, many require professional expertise to ensure safety and proper functioning.

Recognizing Signs of Carbon Monoxide Leaks

Carbon monoxide leaks from furnaces pose a serious threat to your family’s safety. Whether you’ve got a Goodman, Carrier, Lennox, Trane, or Rheem furnace, it’s vital to recognize the signs of a leak.

Be alert for:

- Headaches or dizziness

- Nausea or fatigue

- Flu-like symptoms

- Sooty or brownish-yellow stains around the heating apparatus

- Pilot light that’s yellow instead of blue

Don’t ignore these warnings. Install carbon monoxide detectors and address any furnace issues promptly to protect your household.

Dealing with Overheating Issues

Furnace overheating can quickly escalate from a minor issue to a major safety hazard. It’s often caused by a cracked heat exchanger, improperly sized ductwork, or a faulty blower.

If your furnace feels unusually hot or shuts off repeatedly, ventilate the area immediately. For two-stage or modulating valve systems, call a professional if temperatures exceed 170 degrees Fahrenheit. Don’t attempt repairs yourself; prioritize safety and expert assistance.

Understanding the Risks of DIY Furnace Repair

Although DIY repairs can save money, attempting to fix your furnace yourself can be extremely dangerous. Whether you have a single-stage, natural draft, or non-condensing furnace, safety should be your top priority.

Consider these risks before attempting repairs:

- Gas leaks leading to fire or explosion

- Carbon monoxide poisoning

- Electrical shocks

- Damage to expensive components

- Voiding your warranty

Call a professional for issues affecting seasonal efficiency, quiet operation, Wi-Fi connectivity, or remote monitoring features.

Preventive Maintenance to Avoid Frequent Shutoffs

To keep your furnace running smoothly and avoid frequent shutoffs, you’ll need a solid preventive maintenance plan.

Start by setting up a regular cleaning schedule for your furnace and its components. Don’t forget to book annual professional inspections and consider upgrading to more reliable furnace parts if needed.

Establishing a Regular Cleaning Schedule

By implementing a regular cleaning schedule for your furnace, you’ll greatly reduce the risk of frequent shutoffs and ensure excellent performance throughout the heating season. Focus on these key areas:

- Replace the air filter every 1-3 months

- Clean the blower wheel annually

- Keep vents and registers unobstructed

- Schedule professional tune-ups

- Maintain the flame sensor

This routine helps prevent issues like a defective gas valve and ensures your furnace, whether it’s AFUE 80, 90, 95, 97, or 98, operates efficiently.

Performing Annual Professional Inspections

Annual professional inspections are critical for maintaining your furnace’s health and preventing frequent shutoffs. These inspections check your furnace’s AFUE rating, BTU output, and energy efficiency.

A professional can spot issues with modulating systems and ensure even heat distribution. They’ll verify Energy Star certification and propose upgrades for cost savings. Regular inspections help you avoid costly repairs and keep your furnace operating efficiently all winter long.

Upgrading to More Reliable Furnace Components

While professional inspections are key, upgrading your furnace components can substantially reduce the likelihood of frequent shutoffs. Consider these improvements:

- Install a brushless direct current (BLDC) blower motor

- Upgrade to a smart thermostat

- Replace old oil or electric furnaces with dual fuel systems

- Choose a properly sized unit (e.g., 40,000 BTU)

- Opt for direct vent or power vent models

These upgrades boost reliability, efficiency, and performance, helping prevent unwanted shutdowns.