Rust on gas pipes is a red flag for dangerous leaks, potential explosions, and fire hazards. Over time, rust degrades metal, turning it into brittle iron oxide that compromises the strength and function of gas lines. To mitigate these risks, it is crucial to have regular inspections and maintenance of gas lines, especially in older buildings. Investing in professional gas line installation or replacement from licensed technicians can significantly reduce the likelihood of rust-related issues, ensuring safe and reliable operation. Addressing any signs of corrosion promptly can prevent catastrophic failures and enhance the longevity of the gas system. Properly following the gas line installation steps in Ontario is essential to ensure compliance with safety regulations and standards. Homeowners should also educate themselves on the importance of corrosion prevention methods and protective coatings that can extend the lifespan of gas lines. By taking proactive measures, including regular monitoring and addressing any early signs of wear, the safety and efficiency of gas systems will be greatly improved. In addition to monitoring for rust and corrosion, homeowners should be vigilant about loose gas line connection, which can lead to leaks and pose serious safety threats. Ensuring all connections are secure and properly installed is vital to maintaining a safe gas system. Regular checks and professional assessments can help identify potential problems before they escalate, providing peace of mind and a safer living environment.

Let’s break down what causes rust on gas pipes and what you can do about it.

Key Takeaways on Rust on Gas Pipes

- Rust on gas pipes increases the chance of gas leaks, fires, and explosions.

- Corrosion weakens pipe walls, compromising structural integrity.

- Unchecked rust spreads, complicating repairs and driving up costs.

- Prevention methods include coatings, cathodic protection, and environment management.

- Addressing existing rust requires inspection, repair, or full replacement for safety.

Rust on Gas Pipes: Understanding Corrosion

How Rust Forms on Gas Pipes

Rust on gas pipes develops through electrochemical reactions between oxygen, water, and metal. These processes gradually degrade the metal surface:

- Iron reacts with oxygen and moisture to form iron oxide (Fe₂O₃).

- Water accelerates the breakdown process.

- Contact between dissimilar metals like steel and copper can intensify corrosion.

Understanding these chemical interactions helps identify rust sources and implement long-term solutions.

Types of Corrosion Impacting Gas Lines

Gas pipes suffer from multiple forms of corrosion. The most common types include:

- Surface corrosion: Caused by humidity or water exposure, weakening pipes over time.

- Galvanic corrosion: Occurs when different metals come into contact, often around fittings or valves.

Using quality materials and anti-rust coatings like Rust-Oleum Stops Rust reduces these risks. Addressing water accumulation is also essential.

What Speeds Up Rust on Gas Infrastructure

Several environmental and operational factors accelerate rust formation on gas pipes:

- Underground moisture and soil chemicals.

- Condensation and water pooling.

- Poor airflow in enclosed areas.

- Lack of rust-inhibiting treatments (e.g., CRC, Boeshield).

Regular inspections and early interventions can prevent hazardous failures.

Rust on Gas Pipes: How to Identify It

Detecting rust on gas pipes early helps avoid expensive and dangerous problems.

Signs of Rust on Gas Pipes

Visual cues often reveal rust damage. Look for:

- Discoloration or staining on the pipe.

- Small surface pits or holes.

- Flaking paint or bubbling coatings.

- Reddish powder or rust flakes.

If you notice these signs, further testing is needed to assess the severity.

Non-Invasive Testing for Pipe Corrosion

To avoid damaging pipes during inspection, professionals use tools like:

- Ultrasonic thickness gauges (e.g., Cygnus 4+)

- Magnetic flux leakage detectors

- X-ray imaging

- Magnetic particle test kits

These methods provide a full picture of internal and external pipe health without interrupting service.

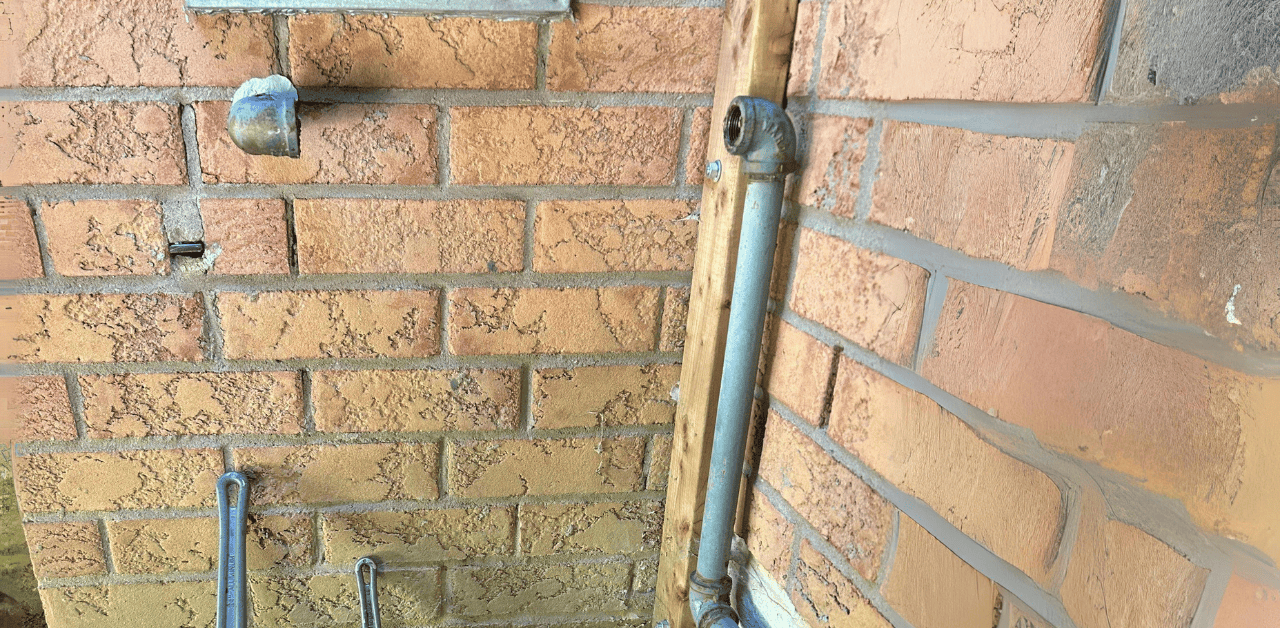

Rust-Prone Areas in Gas Lines

Rust on gas pipes tends to form in vulnerable spots:

- Pipe joints and fittings exposed to moisture.

- Gas meter connections with poor shielding.

- Zones lacking cathodic protection.

- Low-lying pipe sections where water accumulates.

Focusing maintenance on these areas prevents rust from spreading.

Rust on Gas Pipes: Safety Implications

Rusty gas pipes are very dangerous and shouldn’t be ignored. Old, worn-out pipes can break easily, causing big gas leaks. These leaks make fires and explosions more likely to happen. Also, the leaking gas can let out harmful fumes. If not fixed, these fumes can make you and your neighbours very sick. It’s important to deal with rusty gas pipes right away to keep everyone safe.

Compromised Pipe Strength and Leak Hazards

Corroded gas pipes lose thickness, weakening their ability to handle pressure:

- Brittle pipes can rupture under stress.

- Slow leaks may go undetected and build up dangerous gas levels.

- Sparks or electrical shorts near rusted sections could ignite gas.

Flexible gas lines, anti-rust coatings, and leak detector devices help mitigate these threats.

Fire and Explosion Risks from Rust Damage

Rust on gas pipes can lead to sudden failures. Even a small crack can leak gas, which might ignite with the slightest spark.

Frequent inspections and immediate replacement of corroded pipes help reduce fire and explosion risk.

Health Risks from Leaking Gas

Leaking gas from rusty pipes is toxic. Exposure can cause:

- Headaches, dizziness, or nausea.

- Loss of consciousness.

- Long-term respiratory or neurological damage.

Install gas alarms, ensure proper ventilation, and use leak detection tools to protect occupants.

Rust on Gas Pipes: Preventive Measures

Keeping your gas pipes in good shape for a long time requires active steps to prevent damage. You can guard your pipes from rust by putting on protective layers and using special systems that stop corrosion. Also, managing the area around your pipes can greatly lower the chance of rust forming. Regular inspections can help identify potential issues before they become serious problems, allowing for timely repairs. It’s also important to know how to address low gas pressure, as this can be a sign of underlying issues that need immediate attention. Proper maintenance and vigilant monitoring will ensure the longevity and safety of your gas piping system.

Protective Coatings and Their Application in Gas Pipe Maintenance

A good way to fight gas pipe rust is by using protective coatings. These coatings can make pipes last longer and work better. Some useful coatings are polyurethane, zinc-rich primers, fusion-bonded epoxy (FBE), and coal tar coatings.

They create a shield against things that cause rust, stopping the pipes from breaking down. Other special coatings like 3M Scotchkote, Carboline Rustbond, and Sherwin-Williams Macropoxy 646 can also help pipes resist rust.

When put on properly, these coatings can make gas pipes last longer. This means less money spent on fixing pipes and more reliable gas delivery to people’s homes.

Cathodic Protection Systems for Underground Gas Pipes

Cathodic protection is another good way to stop rust on underground gas pipes. This method uses electric current to fight the rusting that damages metal over time.

By putting special metal pieces called anodes along the pipe, you can make a controlled current that protects the pipes from a type of rust called galvanic corrosion. This works for different kinds of pipes, like copper, corrugated stainless steel, or plastic gas pipes. It can also be adjusted for different soil types and weather conditions that affect how fast things rust.

When used with other rust-stopping methods, like oil or water rust blockers and special vapours that prevent rust, cathodic protection helps keep your underground gas pipes safe for a long time.

Environmental Control Strategies to Minimize Corrosion Risk

Looking at ways to control the environment can help lower the risk of rust on gas pipes. Good care of the surroundings can stop rust and make these important pipes last longer.

- Keep the right acid levels and watch for factory waste that can speed up rust.

- Lessening changes in heat and cold can cause small holes and cracks in the pipes.

- Choose the best metals, heat them the right way, and treat their surfaces to make the pipes stronger against harsh surroundings.

- Use systems that check the environment all the time to quickly spot and fix things that make rust happen faster.

Rust on Gas Pipes: How to Handle Existing Damage

When rust appears, quick action is crucial. Begin with an accurate assessment to choose the best repair or replacement plan.

Evaluating Rust Severity

Classify corrosion to guide repair decisions:

- Surface rust: Cosmetic damage only.

- Moderate corrosion: Wall thinning without deep penetration.

- Severe rust: Significant structural weakening.

- Perforation: Full breaches in the pipe wall.

Factors like pipe age, material type, and internal configuration affect decisions.

Repairing Medium Rust Damage

Moderate corrosion may be addressed using:

- Epoxy coatings or wrap systems.

- Flexible liners or internal sprays.

- Corrugated stainless steel tubing.

Ensure all work follows inspection standards and safety codes.

Replacing Severely Corroded Gas Lines

When rust on gas pipes reaches critical levels, full replacement is necessary. Use advanced tools like:

- MSA Altair 4XR

- BW GasAlert MicroClip XL

- RKI GX-2009

- Industrial Scientific Ventis Pro5

Follow NFPA and OSHA standards to ensure code compliance and workplace safety.