Furnace flame sensor failures often cause common furnace issues like short cycling, frequent shutdowns, and error codes. If you notice any of these symptoms, your furnace flame sensor might be to blame. Regular maintenance, such as cleaning the flame sensor with fine-grit sandpaper, can prevent most problems and keep your furnace running smoothly. If cleaning doesn’t fix the issue, it might be time to call a professional.

A faulty flame sensor can lead to inefficient heating and pose safety risks. Diagnosing and repairing the flame sensor early is key to avoiding bigger problems. Preventive steps, like annual furnace inspections and keeping the area around the furnace clean, will help extend the sensor’s lifespan and improve furnace efficiency. Understanding how the flame sensor works and maintaining it regularly can save you from costly repairs and heating problems.

Key Takeaways

- Recognize common symptoms of flame sensor failure: short cycling, frequent shutdowns, and specific error codes on the furnace display.

- Clean the flame sensor regularly using fine-grit sandpaper or steel wool to remove buildup and ensure proper functionality.

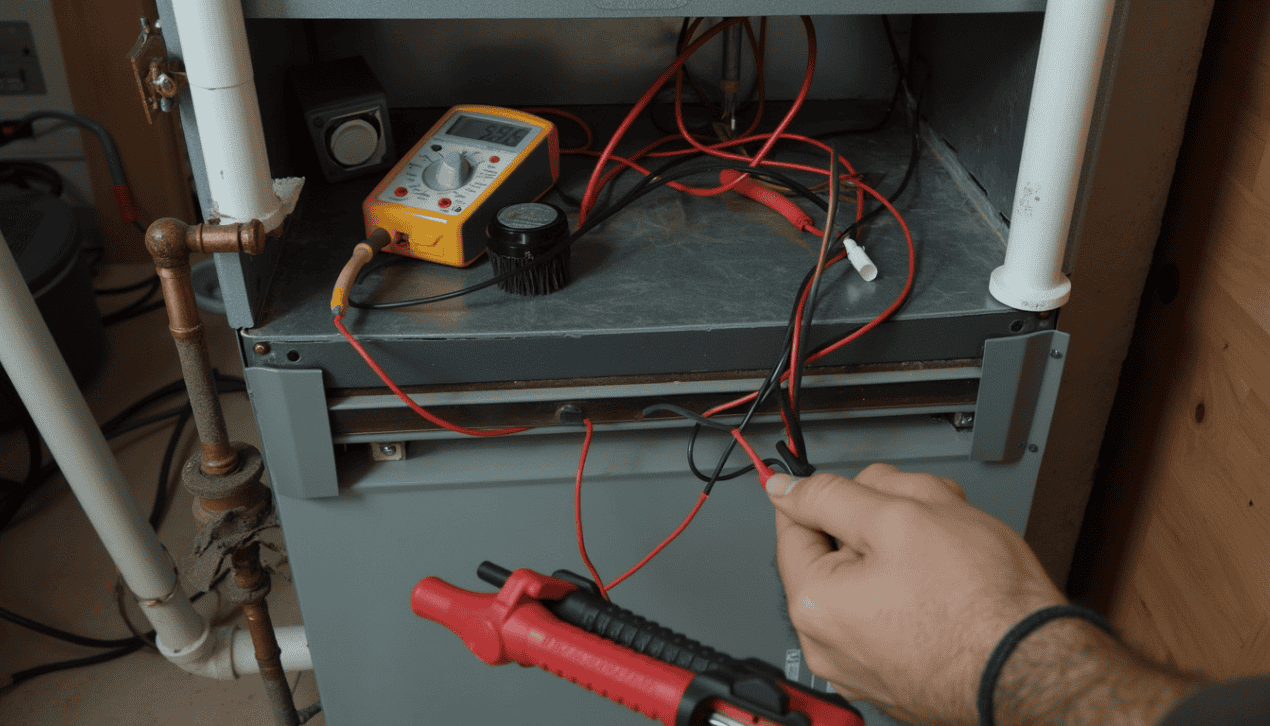

- Test the flame sensor’s continuity using a multimeter to determine if replacement is necessary.

- Ensure proper placement and secure mounting of the flame sensor for accurate flame detection.

- Schedule annual professional furnace maintenance to prevent flame sensor issues and maintain overall system efficiency.

Understanding Furnace Flame Sensors and Their Role

The furnace flame sensor is a critical component that ensures your furnace runs safely and efficiently. It works by detecting the flame when your furnace is on, and shutting off the gas supply if no flame is present. This prevents unburned gas from building up, which can be dangerous.

There are different types of furnace flame sensors, such as thermocouples, optical sensors, and flame rods. Each type has specific features designed for different furnace models. Regardless of the type, regular cleaning and maintenance of your flame sensor are key to avoiding malfunctions and keeping your furnace working properly.

A well-maintained flame sensor helps prevent problems like short cycling and inefficient heating. Knowing how your furnace’s flame sensor operates is crucial for ensuring reliable and safe performance.

How Furnace Flame Sensors Work in Modern Furnaces

In modern furnaces, three main components work together to ensure safety and efficiency: the thermostat, the gas valve, and the furnace flame sensor. The flame sensor, also known as a flame rod, detects whether a flame is present when the furnace is running.

The sensor works through a process called flame rectification, which uses ionization to check if a flame is present. If no flame is detected, the sensor signals the gas valve to shut off the gas, preventing dangerous gas buildup. The control board relies on signals from the flame sensor to regulate gas flow safely.

Understanding how the flame sensor works is important for maintaining furnace safety and keeping your home comfortable.

The Importance of Furnace Flame Sensors for Safety and Efficiency

Understanding The furnace flame sensor is a key safety feature that helps keep your home safe and your furnace running efficiently. It ensures that the furnace only operates when a flame is present. If no flame is detected, the sensor shuts off the gas to prevent dangerous conditions.

Why is the furnace flame sensor important?

- It prevents gas buildup when the furnace isn’t working correctly.

- It helps avoid explosions caused by unburned gas.

- It reduces carbon monoxide risks, protecting your household.

- It ensures your furnace delivers consistent heating and operates efficiently.

Regular maintenance of your flame sensor will help keep your home safe while improving your furnace’s performance

Common Types of Furnace Flame Sensors and Their Characteristics

There are several types of furnace flame sensors, each designed to suit different furnace models. The most common types are:

- Straight flame rods: These are the standard sensors found in many furnaces. They’re simple and reliable.

- Curved flame rods: These are used when the furnace design requires the sensor to reach around a specific part of the burner.

- Universal flame sensors: These can be installed in multiple furnace models and are flexible in terms of compatibility.

Regular cleaning and maintenance of each of these furnace flame sensors are essential to keep them functioning properly and to avoid issues like short cycling or shutdowns.

Identifying Symptoms of a Faulty Furnace Flame Sensor

Recognizing the symptoms of a faulty furnace flame sensor is key to ensuring timely repairs and avoiding larger issues. Here are some common signs of flame sensor problems:

- Short cycling: Your furnace turns on but quickly shuts off.

- Frequent shutdowns: The furnace unexpectedly stops running, leaving your home cold.

- Error codes: You may see error codes on the furnace display, often related to flame detection issues.

It’s important to remember that similar symptoms can also be caused by thermostat malfunctions. Make sure to check the thermostat settings as part of your diagnostic process. Differentiating between flame sensor issues and other furnace problems is crucial for a proper diagnosis and repair.

Recognizing Short Cycling and Frequent Shutdowns

A malfunctioning flame sensor in a furnace often manifests through several distinct symptoms, primarily short cycling and frequent shutdowns. As homeowners, we should be aware of these signs:

- Furnace short cycling, where the burner ignites but quickly shuts off

- Inconsistent heating throughout our home

- Repeated safety ignition lockouts after three failed attempts

- Burner flames or pilot lights that extinguish shortly after ignition

These issues can cause flame failure, insufficient heating, and higher energy bills. In some cases, short cycling may also result from thermostat issues or a dirty air filter, which can cause the furnace to overheat. Regular maintenance and proper airflow can help avoid these problems.

Interpreting Error Codes and Warning Signs

Error codes on your furnace display are often linked to flame sensor problems. Look out for:

- Frequent on-off cycling: Your furnace turns on and off repeatedly without fully heating the house.

- Flame extinguishing: The burner flame goes out soon after ignition.

- Inconsistent heating: Some rooms remain colder than others.

These signs could indicate gas emission without ignition, which may be related to the flame sensor. Sometimes, short cycling can be caused by thermostat malfunctions or dirty air filters, which may mimic flame sensor problems. Proper diagnosis is crucial to avoid unnecessary repairs and resolve the root cause.

Distinguishing Flame Sensor Issues from Other Furnace Problems

Furnace troubleshooting requires careful differentiation between flame sensor issues and other potential problems. Homeowners can identify flame sensor malfunctions by watching for these signs:

- Frequent on-off cycling of the furnace

- Burner flame extinguishing shortly after ignition

- The pilot light repeatedly goes out

- Inconsistent heating throughout the home

These signs often point to a faulty flame sensor. However, some of these symptoms could also overlap with other furnace issues like thermostat problems or dirty air filters. Checking these components as part of your furnace troubleshooting can prevent misdiagnosis. Regular maintenance, including filter changes, will help keep your furnace running smoothly and efficiently.

Diagnosing Flame Sensor Issues

Diagnosing flame sensor issues begins with a visual inspection by homeowners to check for visible damage or buildup. Like pressure switch troubleshooting, homeowners should look for signs of malfunction such as the furnace not starting or shutting off unexpectedly.

For more precise diagnosis, professionals use multimeters and other specialized tools to test the sensor’s functionality and electrical connections. When homeowners are unsure about the problem or lack the necessary tools, it’s best to call a qualified technician for advanced diagnosis and repair.

Visual Inspection Techniques for Homeowners

To empower homeowners in identifying potential flame sensor issues, visual inspection serves as a pivotal first step. By examining the flame sensor, you can spot common problems:

- Look for physical damage like cracks or bends

- Check for carbon buildup on the sensor rod

- Observe any discolouration or corrosion

- Guarantee proper positioning within the burner assembly

These visual cues help us detect issues early, fostering a sense of control over our home’s heating system.

Using Multimeters and Other Diagnostic Tools

While visual inspection provides valuable initial insights, advanced diagnostic tools offer a more precise assessment of flame sensor functionality. Homeowners can use multimeters to measure resistance and voltage, ensuring proper electrical connections. Microamp meters help measure the sensor’s current output during operation.

For more complex issues, professional HVAC technicians may employ diagnostic scanners to identify specific fault codes and pinpoint problems accurately. These tools empower us to maintain our furnaces effectively.

When to Call a Professional for Advanced Diagnosis

Despite the availability of diagnostic tools for homeowners, certain flame sensor issues require the expertise of a professional HVAC technician. Consider calling licensed HVAC technicians when:

- System diagnostics consistently fail

- Error code interpretation is unclear

- Repeated sensor cleaning doesn’t solve the problem

- Furnace cycles on and off frequently

Professionals have advanced tools and knowledge to pinpoint complex issues, ensuring your heating system’s safety and efficiency. Their expertise can save you time and prevent costly mistakes.

DIY Flame Sensor Maintenance and Repair

Maintaining and repairing a furnace flame sensor can be a straightforward DIY task with the right approach.

This section outlines the steps to clean a flame sensor, the necessary tools and materials, and important safety precautions to follow. By understanding these key aspects, homeowners can effectively address flame sensor issues and maintain their furnace’s performance.

Step-by-Step Guide to Cleaning a Flame Sensor

Cleaning a flame sensor is a straightforward task that homeowners can often perform themselves, potentially saving on service calls. Follow these DIY maintenance tips for cleaning the sensor:

- Turn off power to the furnace

- Locate and remove the flame sensor

- Gently clean with fine-grit sandpaper or steel wool

- Reinstall and test the furnace

These simple cleaning procedures can help keep your furnace running smoothly and efficiently, giving you peace of mind during cold months.

Tools and Materials Needed for Flame Sensor Maintenance

What tools and materials do you need to perform DIY flame sensor maintenance? For cleaning, gather a wrench or driver, sandpaper or steel wool, and a clean cloth.

For multimeter testing and flame signal strength measurement, you’ll need a multimeter and a test lamp.

When considering sensor replacement, guarantee compatibility with your furnace model. These tools will help you maintain your flame sensor, keeping your furnace running smoothly and efficiently.

Safety Precautions When Working with Furnace Components

Safety is the top priority when performing DIY flame sensor maintenance and repair on your furnace. Follow these essential precautions to avoid accidents:

- Turn off the power and gas supply before working on the furnace.

- Handle the flame sensor gently to avoid damaging it.

- Always use approved cleaning materials, such as fine-grit sandpaper or steel wool.

- Follow the manufacturer’s instructions to ensure proper handling and installation.

By adhering to these safety steps, you can perform flame sensor maintenance confidently and keep your furnace running safely and efficiently.

Prevention and Long-Term Care for Your Furnace Flame Sensor

Preventing flame sensor failures and ensuring long-term furnace reliability requires a proactive approach. Setting up a regular maintenance schedule, including professional tune-ups and DIY cleaning, is key to extending the sensor’s lifespan. Homeowners can also make simple upgrades to improve furnace performance and reduce the risk of sensor-related issues.

Establishing a Regular Maintenance Schedule

To keep your furnace flame sensor in good condition, follow a regular maintenance routine:

- Schedule annual inspections with HVAC professionals.

- Clean the sensor every 3 to 12 months to remove buildup.

- Replace furnace filters regularly to maintain airflow.

- Follow the manufacturer’s recommendations to avoid unnecessary wear.

Tips for Extending Flame Sensor Lifespan

Maximizing the lifespan of your furnace flame sensor requires a mix of preventive care and long-term strategies:

- Clean the sensor every 3 to 6 months to prevent buildup.

- Ensure proper sensor positioning during furnace tune-ups for optimal performance.

- Protect the sensor from environmental factors, and replace it every 5 to 10 years for safety and efficiency.

By following these steps, you’ll keep your furnace operating safely and extend the life of your flame sensor.

Upgrades and Improvements to Enhance Furnace Reliability

Several upgrades can improve furnace reliability and reduce the chances of flame sensor failure:

- Install high-temperature flame sensors for added durability.

- Upgrade to a high-efficiency furnace model for better performance.

- Add a combustion air intake system to reduce soot buildup.

- Invest in a smart thermostat for more precise temperature control.

These improvements, combined with regular maintenance, will help keep your furnace running efficiently and prevent sensor-related issues.