Furnace limit switch failures can cause significant heating system problems. These switches are vital safety devices that prevent overheating by shutting off the burner when temperatures exceed safe limits. Common symptoms of a faulty limit switch include frequent furnace shutdowns, constant blower operation, and inconsistent heating. Homeowners can perform basic diagnostics like checking for visible damage and ensuring proper furnace placement. However, advanced testing and repairs often require professional furnace repair services. Regular maintenance, including cleaning and inspections, can help prevent limit switch issues and extend their lifespan. Understanding the role of limit switches is essential to maintaining a safe and efficient home heating system.

Key Takeaways

- Identify symptoms of limit switch failure: constant blower operation, frequent shutdowns, error codes, and inconsistent heating.

- Perform basic DIY checks: inspect for dust accumulation, ensure proper furnace placement, and clean accessible components.

- Use a multimeter to test limit switch continuity and resistance, following safety precautions and manufacturer guidelines.

- Understand common error codes related to limit switch issues for accurate diagnosis and troubleshooting.

- Know when to call a professional: for advanced diagnostics, repairs, or when DIY efforts don’t resolve the problem.

Understanding the Furnace Limit Switch

The furnace limit switch plays an indispensable role in maintaining the safe operation of heating systems. Also known as a high-limit switch or temperature safety switch, this device acts as a fail-safe mechanism. The fan limit control monitors the heat exchanger temperature, shutting off the burner if it exceeds a set threshold.

Understanding the function of this component is pivotal for maintaining your heating system and troubleshooting potential issues. This thermal cutoff switch provides imperative overheat protection, ensuring your furnace operates safely and efficiently.

The Role of Limit Switches in Furnace Operation

Building upon the foundational understanding of limit switches, it’s important to examine their specific role in furnace operation. These vital safety mechanisms serve as temperature control devices, preventing overheating. Fixed temperature switches monitor the furnace’s heat levels, triggering an automatic shut-off if temperatures exceed safe limits.

Proper cycling of the furnace is necessary for maintaining energy efficiency and preventing potential damage to the system. This protective function guarantees your home’s safety and the furnace’s longevity, giving homeowners peace of mind during cold Canadian winters.

Types of Limit Switches and Their Functions

Several types of limit switches play critical roles in ensuring the safe and efficient operation of furnaces. These include primary, secondary, and fan limit switches, which use temperature sensing to protect against overheating. Let’s explore the main types and their functions:

| Type | Function | Switch Mechanism |

|---|---|---|

| Primary | First defense | Snap disc |

| Secondary | Backup safety | Bimetal |

| Fan | Blower control | Electromechanical |

| Temperature | Overheat prevention | Snap disc or bimetal |

| Rollout | Flame detection | Snap disc |

How Limit Switches Contribute to Furnace Safety and Efficiency

Limit switches play an indispensable role in ensuring both the safety and efficiency of furnace operations. These temperature sensors are integral to the safety circuit, preventing overheating and maintaining performance consistency.

Furnace limit switches monitor the temperature inside the furnace and shut off the burner when it exceeds a set limit, ensuring safe and efficient operation. Our furnaces rely on limit switches for:

- Emergency shut-off in dangerous situations

- Monitoring the temperature sensing range

- Automatic reset capabilities when conditions normalize

Identifying Symptoms of a Faulty Limit Switch

Recognizing the symptoms of a faulty furnace limit switch is indispensable for maintaining a safe and efficient heating system. Common signs include the blower running constantly, frequent shutdowns, and error codes on the thermostat.

Watch for inconsistent heating, increased energy bills, and the furnace not reaching desired temperatures. Continuous operation of the furnace without shutting off is another key indicator of a malfunctioning limit switch. The limit switch plays an essential role in preventing overheating and ensuring safe operation. Manual and automatic reset switches may be triggered.

If you suspect a faulty limit switch, consult an HVAC technician for proper temperature measurement and component testing.

Common Signs of Limit Switch Malfunction

Frequently, homeowners encounter specific indicators that point to a malfunctioning furnace limit switch. Common signs include furnace short cycling and no heat production.

Inconsistent heating and continuous furnace operation without shutting off are also telltale signs of a faulty limit switch. These issues can lead to increased energy bills and potential damage to other heating system components.

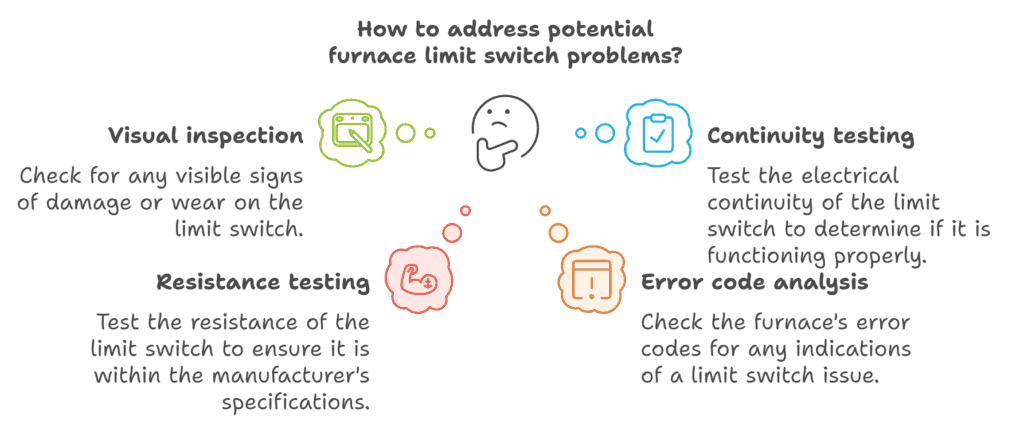

To diagnose the issue, we can perform:

- Visual inspection

- Continuity testing

- Resistance testing

Error code analysis and symptom analysis are also valuable tools. By recognizing these signs early, we can address limit switch problems promptly, ensuring our homes stay warm and comfortable throughout the cold season.

Distinguishing Limit Switch Issues from Other Furnace Problems

When troubleshooting furnace problems, it’s vital to accurately identify whether the limit switch is the root cause or if other components are at fault. Unlike issues with the blower motor, heat exchanger, or control board, limit switch problems often result in improper cycling or constant running.

A malfunctioning limit switch can lead to inconsistent heating and increased energy bills, making it paramount to diagnose correctly. While a faulty thermostat, flame sensor, pressure switch, or roll-out switch may exhibit similar symptoms, checking the limit switch’s continuity and connections can help pinpoint the issue.

Interpreting Error Codes Related to Limit Switch Failures

Error codes play a pivotal role in diagnosing limit switch failures in furnaces. These codes provide critical information about issues like overheating or airflow problems.

When troubleshooting, consider the following:

- Blinking lights on the control board

- Specific error code meanings

- Furnace reset and monitoring

Understanding bimetallic strip behaviour, normally closed (NC) and normally open (NO) switches, setpoint temperature, and hysteresis is indispensable. Thermal protection and fail-safe operation guarantee your furnace’s safety. Consult manufacturer documentation for precise interpretation.

Inconsistent heating and continuous operation are common signs of a faulty limit switch, which can lead to increased energy bills and potential damage to other components.

Diagnosing Limit Switch Issues

For accurate diagnosis of limit switch issues, a systematic approach is crucial. Begin by checking the hvac system for visible signs of electrical malfunction or mechanical wear. Use a multimeter to test the switch’s continuity.

Inconsistent heating and continuous furnace operation are key indicators of a faulty limit switch that should be investigated. Licensed hvac technicians can provide expert diagnosis, especially when diagnostic accessibility is restricted. Combine error code interpretation with physical inspection to pinpoint the problem. This thorough approach guarantees accurate identification of limit switch issues.

DIY Checks for Homeowners

While professional diagnosis is often necessary, homeowners can perform several preliminary checks to identify potential limit switch issues. Understanding furnace components and recognizing warning signs are indispensable for DIY safety checks.

Proper furnace placement and adequate clearance around the unit are vital for ideal performance and safety. Maintaining sufficient space allows for better airflow and easier access during inspections.

- Inspect for dust accumulation

- Learn basic cleaning procedures

- Familiarize yourself with cleaning requirements

Using Multimeters and Other Tools to Test Limit Switches

Multimeter mastery empowers homeowners to perform basic diagnostic tests on furnace limit switches. Conducting continuity tests and resistance measurements helps identify open or short circuits. Non-contact voltage testers check power flow. Regular inspections reveal physical damage.

| Test Type | Purpose | Interpretation |

|---|---|---|

| Continuity | Functionality | Open/Closed |

| Resistance | Temperature thresholds | Ohm values |

| Voltage | Power supply | Presence/Absence |

Consult furnace documentation or HVAC professionals for accurate calibration, voltage drop analysis, and replacement interval recommendations.

When to Call a Professional for Advanced Diagnostics

Although homeowners can perform basic diagnostics, certain situations necessitate professional intervention. HVAC engineers possess specialized tools and expertise for complex issues. ALP Heating Services offers fast, reliable furnace repair with TSSA-certified technicians for all property types. Their emphasis on safety and efficiency guarantees quality service delivery.

Consider calling experts when:

- Basic tests yield inconclusive results

- Frequent limit switch failures occur

- Safety concerns arise

Professionals use advanced equipment like diagnostic scanners, combustion analyzers, and thermal imaging cameras to conduct thorough system diagnostics. These tools help determine failure rates and identify underlying problems.

In emergencies, repair technicians can quickly address dangerous situations, safeguarding your family’s safety and comfort.

Repairing and Replacing Faulty Limit Switches

Repairing or replacing a faulty limit switch requires careful assessment and precise execution. Furnace installers and maintenance specialists can address issues like improper calibration or adjusting temperature switches. The ease of replacement depends on the model. Regular safety inspections help prevent failures.

| Issue | Solution |

|---|---|

| Improper calibration | Recalibrate |

| Worn-out switch | Replace |

| Incorrect settings | Adjust |

| Damaged wiring | Repair |

The calibration process guarantees ideal furnace performance. Homeowners should trust professionals for these tasks to maintain safety and efficiency.

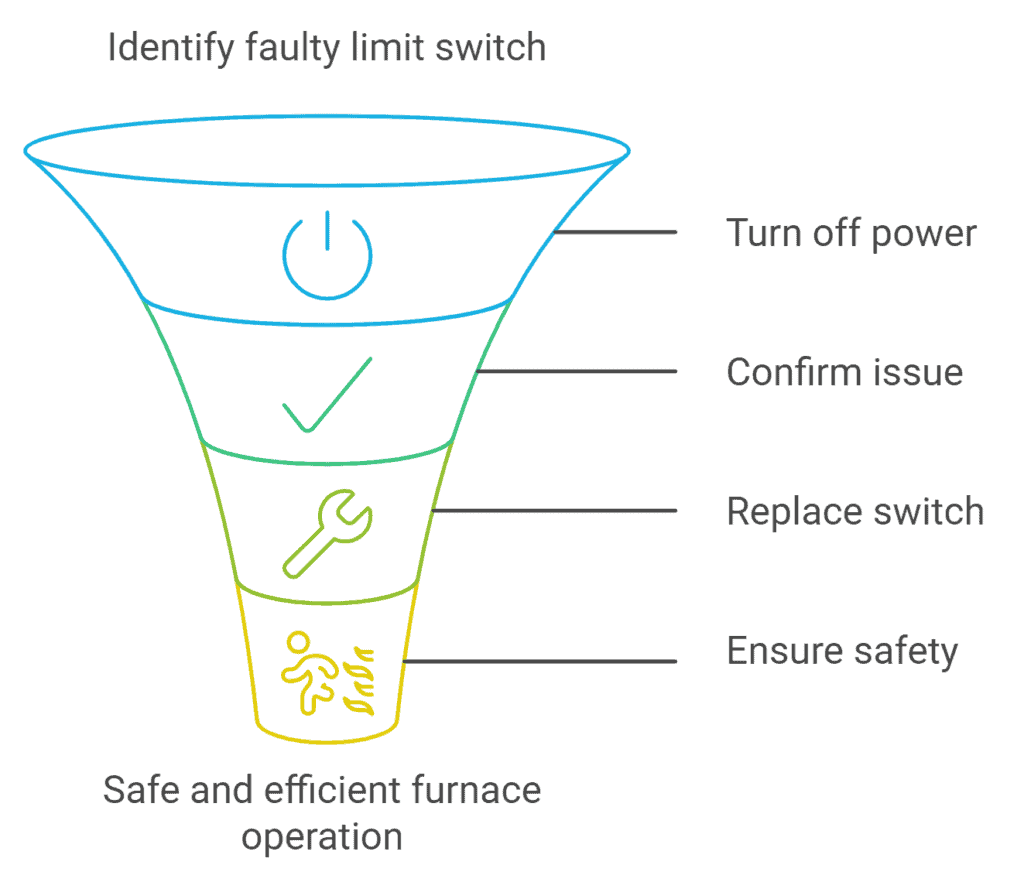

Steps for Safe Limit Switch Replacement

For safe limit switch replacement, following a systematic approach is indispensable. Whether dealing with gas, oil, or electric furnaces, homeowners should prioritize safety standards. Familiarize yourself with single-pole and double-pole switches common in heating systems.

Maintaining proper clearance around furnaces is vital for safety and efficient operation. Guarantee the area is free from flammable items and clutter before beginning any work.

- Turn off the power to the furnace

- Identify the faulty limit switch

- Use electrical testing tools to confirm the issue

Always consult a professional if unsure. Together, we can guarantee our homes stay warm and safe.

Choosing the Right Replacement Switch for Your Furnace

When it comes to selecting a replacement limit switch for your furnace, precision is paramount. Consider these factors:

| Brand | Features |

|---|---|

| Honeywell | Wide compatibility, reliable performance |

| White-Rodgers | Affordable, readily available parts |

| Robertshaw | Long-term durability, precise controls |

| Universal Fit | Adaptable to various furnace models |

| OEM Replacement | Exact match for your specific furnace |

Choose a switch that fits your furnace model, budget, and long-term needs. Prioritize reliability and compatibility to guarantee excellent performance and safety.

Importance of Professional Installation and Calibration

Proper installation and calibration of a furnace limit switch are crucial steps that should never be overlooked. As fellow homeowners, we rely on HVAC system designers to safeguard our safety and comfort. Professional installation is critical for excellent performance and safety, making certain that all components, including the limit switch, function correctly within the system.

Brands like Emerson and Camstat offer reliable options with extended lifespans. Professional installation guarantees:

- Compatibility with safety standards

- Proper integration with the control board

- Correct adjustability for remarkable performance

Relying on experts ensures our furnaces operate efficiently and safely, giving us peace of mind.

Preventing Future Limit Switch Problems

Regular maintenance and proactive measures can greatly reduce the likelihood of future limit switch problems in your furnace. Annual tune-ups by professionals are vital, including component inspections and electrical connection checks. For homeowners, adopting energy-saving practices can help prevent switch failures.

| Maintenance Task | Frequency | Performed By |

|---|---|---|

| Component inspection | Annually | Professional |

| Lubrication | As needed | Professional |

| Filter replacement | Monthly | Homeowner |

Two-stage furnaces and thermistor-based switches may require specialized care. Consult your manual for specific maintenance needs.

Regular Maintenance Practices to Extend Switch Life

Several key maintenance practices can considerably extend the life of a furnace limit switch. Regular attention to air filters, routine inspections, and proper installation are essential. Efficient furnace operation depends on these preventive measures, which also contribute to overall system longevity.

Homeowners can protect their furnaces by:

- Cleaning or replacing air filters regularly

- Scheduling seasonal checkups and tune-ups

- Maintaining detailed service records

These preventive maintenance steps help confirm ideal airflow, identify potential issues early, and provide valuable information for diagnosing recurring problems. By adopting these practices, you’ll safeguard your furnace and limit switch.

Improving Overall Furnace Efficiency to Reduce Strain on Components

Efficiency is the cornerstone of a well-functioning furnace system, directly impacting the longevity of its components, including the limit switch. Proper airflow management and routine vent checks are indispensable for excellent performance.

Rearranging furniture to avoid blocking vents can markedly improve warm air distribution throughout your home. Upgrading to high-efficiency modulating furnaces from brands like Carrier, Lennox, or Rheem can reduce strain on the limit switch.

Energy auditors can assess your home’s insulation and ductwork, recommending improvements to maximize airflow. Regular filter maintenance and using temperature and pressure measurement tools guarantee peak performance, safeguarding essential components.

Upgrading to More Reliable Limit Switch Technologies

While optimizing overall furnace efficiency is critical, upgrading to more reliable limit switch technologies can dramatically enhance system performance and safety. Modern electronic limit switches offer:

- Precise temperature monitoring

- Faster response times

- Advanced safety features

These upgrades can prevent overtemperature conditions and reduce emergency overrides. Some designs incorporate dual sensors and smart diagnostics, improving system reliability. Newer switches may also integrate pressure and airflow sensors, enhancing energy efficiency. Natural gas furnaces, known for their high efficiency of up to 98%, can particularly benefit from these advanced limit switch technologies.

Regular cleaning cycles and maintenance are still necessary for ideal performance.

Troubleshooting Furnace Limit Switch Issues

A functioning furnace limit switch is essential for safe and efficient heating. This critical component monitors furnace temperature, preventing overheating by shutting off the burner when necessary. When a furnace high limit switch malfunctions, common symptoms include:

- Blower fan running constantly without shutting off.

- Frequent furnace shutdowns or irregular cycling.

- Uneven heating and failure to maintain desired temperatures.

- Error codes signaling limit switch HVAC issues.

To address minor issues, you can reset the switch:

- Turn off the furnace’s power supply.

- Locate the limit switch near the burner or heat exchanger.

- Press the reset button gently until it clicks.

- Restore power and test the furnace.

If these steps don’t resolve the problem, consult a professional for advanced diagnostics. Regular maintenance, such as cleaning air filters and scheduling annual inspections, can prevent future furnace limit switch errors and keep your heating system operating smoothly.

Conclusion

Furnace limit switches play a vital role in safe and efficient heating system operation. Understanding their function, recognizing failure symptoms, and implementing preventive measures are indispensable for homeowners. Regular maintenance, including cleaning and inspections, can extend switch life and overall furnace performance. Upgrading to modern limit switch technologies may offer improved reliability. By addressing limit switch issues promptly and proactively, homeowners can guarantee their heating systems operate safely and efficiently for years to come.