A stuck furnace blower motor typically results from bearing failure, faulty capacitors, or mechanical obstructions. First, guarantee safety by disconnecting the power at the circuit panel. Listen for unusual noises and check for visible obstructions in the blower assembly. Common quick fixes include gently tapping the motor housing to free seized components and lubricating accessible bearings. However, these are temporary solutions for a potentially serious issue.

While some problems can be resolved with basic maintenance, electrical issues or mechanical failures often require professional attention. Understanding the root cause will help determine the most effective solution for your specific situation.

Quick Fixes and Key Insights for Homeowners

- Disconnect power and check for mechanical obstructions like debris in the blower wheel causing motor binding.

- Test the capacitor with a capacitance meter, as faulty capacitors often prevent motor start-up.

- Listen for grinding sounds and inspect bearings for wear, adding lubrication if accessible.

- Gently tap the motor housing to free seized components, but avoid excessive force that could cause damage.

- Check electrical connections for loose wires and use a multimeter to verify the proper voltage supply.

Why Do Furnace Motors Get Stuck? Understanding Common Causes

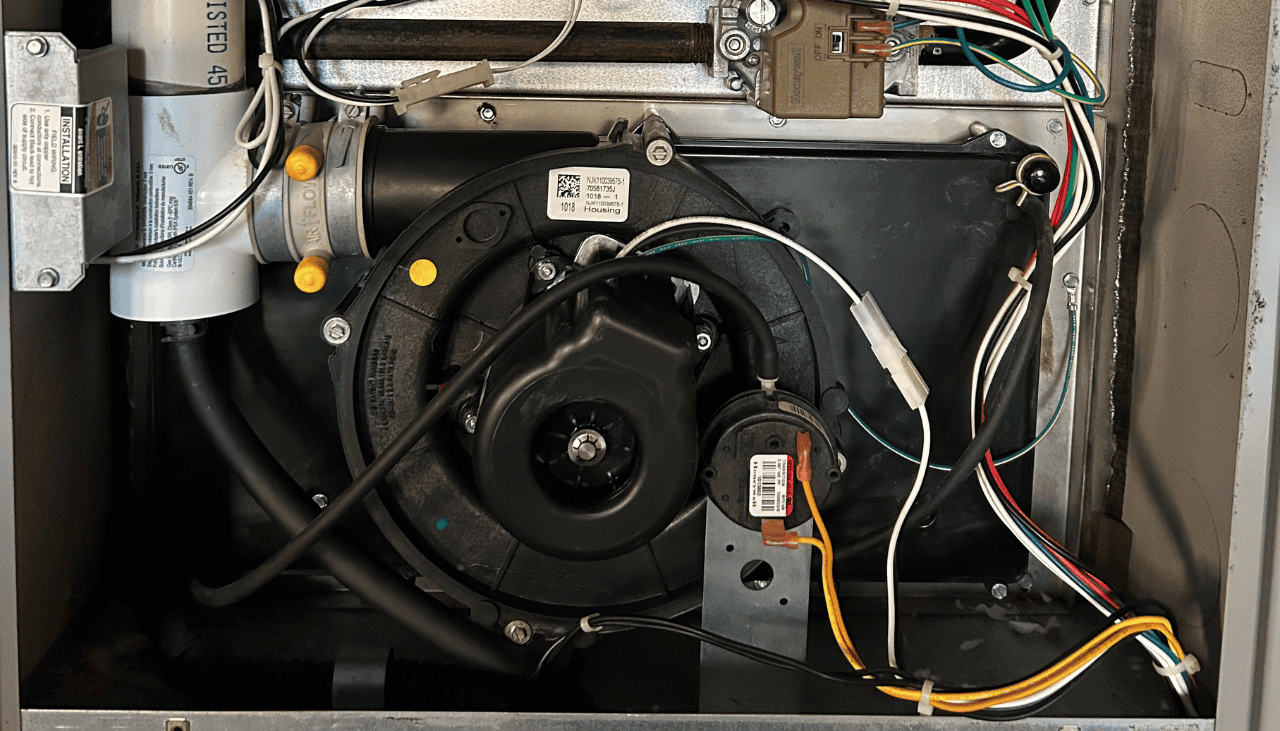

When a furnace blower motor stops working, several common issues can be the root cause. Bearing failure and seizure often result in a complete motor lockup, while electrical component problems like faulty capacitors can prevent proper start-up.

Physical obstructions in the blower assembly may also restrict motor movement, requiring thorough inspection and removal of any debris that could impede operation. Regular filter changes can prevent debris buildup and reduce strain on the blower motor, helping avoid these common issues.

Worn Bearings and Motor Seizure

The failure of motor bearings represents one of the most common mechanical issues in furnace blower systems. When bearings wear down over time, they can create excessive friction within the motor housing, leading to complete seizure.

Seized bearings often produce distinct grinding or squealing noises before failing completely. Regular maintenance and proper lubrication can prevent premature bearing failure and extend motor life.

Electrical Failures and Capacitor Problems

Several electrical component failures can cause a furnace blower motor to become inoperative. A faulty capacitor often prevents the motor from receiving proper starting power, while damaged circuit boards can disrupt crucial control signals.

Electrical failure may also stem from loose connections, worn wiring, or voltage irregularities. These issues typically require professional diagnosis and repair to restore proper motor function.

Blockages and Mechanical Obstructions

Inside furnace blower assemblies, mechanical obstructions can severely impair motor operation through various physical impediments. Common issues include debris blockage from dust, leaves, or small objects that become trapped in the system.

Using a screwdriver set and pliers, technicians can carefully remove these obstructions, but proper safety protocols must be followed to prevent damage to delicate components during cleaning.

Step-by-Step Guide to Diagnosing Furnace Motor Issues

When diagnosing a problematic furnace blower motor, the first pivotal step is to guarantee all power sources are disconnected to prevent electrical hazards during inspection.

A thorough assessment requires vital tools, including a multimeter for electrical testing and a capacitance meter to evaluate the motor’s start capacitor.

While many homeowners can perform basic diagnostic procedures, complex issues involving electrical components or mechanical failures often warrant the expertise of a qualified HVAC technician.

Following manufacturer installation guidelines during replacement is critical for the optimal performance and safety of the blower motor system.

Safety First: Inspection Checklist for Homeowners

Before attempting any furnace blower motor repairs, a thorough safety inspection must be conducted to protect both the technician and the equipment. Always wear safety glasses and work gloves before beginning the inspection.

Use a voltage tester to confirm power is completely disconnected at the electrical panel. Check surrounding areas for water damage, exposed wiring, or other potential hazards that could compromise safety during repairs.

Essential Tools for Testing Furnace Motors

For accurate diagnosis of furnace blower motor issues, technicians must have several pivotal testing tools in their arsenal. A quality multimeter is indispensable for testing voltage and continuity, while insulated tools guarantee the safe handling of electrical components.

Wire strippers are necessary for examining and repairing damaged wiring. These tools allow technicians to safely troubleshoot and identify the root cause of motor problems.

Should You Fix It Yourself or Call a Pro?

A critical decision homeowners face when encountering furnace blower motor problems is whether to attempt repairs themselves or seek professional help. While basic tasks like checking the motor shaft for free movement can be DIY-friendly when wearing a face mask, complex issues involving electrical windings or internal components are best left to qualified technicians who have proper diagnostic tools and expertise.

Emergency Furnace Repairs: What to Do When Time Is Critical

When faced with a stuck furnace blower motor, homeowners can attempt simple emergency fixes like gently tapping the motor housing with a rubber mallet to free seized components. Safety remains paramount during any repair attempt, requiring complete power disconnection and careful handling of all mechanical parts.

If initial troubleshooting fails or if there are signs of electrical burning, smoke, or unusual noises, it’s crucial to contact a qualified HVAC technician immediately rather than risk further damage or safety hazards. Regular limit switch maintenance helps prevent blower motor issues by ensuring proper temperature control and cycling of the furnace system.

Quick Fixes to Get Your Furnace Running

Several temporary solutions can help restore function to a stuck furnace blower motor while awaiting professional repairs. For belt issues, adjusting tension or applying belt dressing may provide short-term relief.

Adding appropriate motor oil or lubricant to accessible bearings can sometimes free up a seized motor. Gently tapping the motor housing with a rubber mallet might also help break through minor mechanical binding.

Staying Safe During Emergency Repairs

Safety must take precedence when attempting any emergency repairs on a furnace blower motor. Before touching any HVAC motor components, guarantee the power is completely disconnected at both the furnace switch and circuit breaker.

When working with an induction motor, watch for sharp edges, hot surfaces, and stored electrical charge in capacitors. Never bypass safety switches or work alone on blower motor repairs.

Knowing When to Call the Experts

Professional HVAC technicians should be contacted immediately if homeowners encounter any of these serious warning signs: burning odours, smoke, excessive noise, complete system failure, or if basic troubleshooting steps prove ineffective.

Additionally, issues involving burnt windings, damaged capacitors, or failing motor bearings require specialized expertise and replacement parts that only qualified technicians can safely address.

Keep Your Furnace Motor Running Smoothly with Preventive Maintenance

A solid preventive maintenance strategy is critical for keeping your furnace blower motor running smoothly and avoiding costly breakdowns. Regular inspections should occur at least twice yearly, focusing on proper lubrication of moving parts and early detection of wear patterns in critical components.

Following manufacturer guidelines for component replacement timelines, particularly for bearings and capacitors, helps guarantee ideal performance and extends the life of your blower motor system. Dirty furnace filters can significantly reduce system efficiency and force your blower motor to work harder than necessary, potentially leading to premature failure.

How Often Should You Inspect Your Furnace?

Regular maintenance inspections of your furnace blower motor serve as a critical foundation for preventing unexpected breakdowns and extending equipment life.

Schedule monthly checks of the fan motor, belts, and components to catch early signs of bearing failure.

Create a maintenance calendar that includes testing motor operation, inspecting belt tension, and listening for unusual noises that could indicate developing problems.

Why Lubrication is Key to Longevity

Proper lubrication serves as a cornerstone of preventive maintenance for furnace blower motors, building upon the benefits of routine inspections. Regular application of manufacturer-recommended lubricants helps prevent wear on replacement bearings and reduces stress on mounting brackets.

Guaranteeing specific lubrication requirements guarantees smooth operation extends motor life, and helps avoid costly emergency repairs during peak heating seasons.

Timelines for Replacing Key Furnace Components

Establishing a strategic component replacement timeline enables homeowners to manage their furnace maintenance before critical parts fail proactively.

Most modern Emerson and Mars blower motors last 15-20 years, while capacitors typically need replacement every 5-7 years.

Regular inspections can identify worn components, allowing for planned replacements during the off-season rather than facing emergency repairs mid-winter.

Should You Replace or Upgrade Your Furnace Blower Motor?

When considering a furnace blower motor replacement, selecting the right motor type is essential for compatibility with your existing system, whether it’s a direct drive or belt-driven configuration. Professional installation confirms proper setup and ideal performance, helping prevent future issues and maximizing the motor’s lifespan.

While the initial cost of a new motor may seem significant, upgrading to a more energy-efficient model often provides long-term savings through reduced power consumption and improved reliability.

Choosing the Right Motor for Your Home

For residential furnace replacements, selecting the right blower motor type is pivotal for ideal system performance and efficiency. When choosing between a standard circulation motor, ECM, or variable speed unit, consider these crucial factors:

- Energy consumption ratings and operational costs

- Airflow requirements for your specific home layout

- Compatibility with existing HVAC components

- Climate conditions and seasonal demands in your region

For residential furnace replacements, selecting the right blower motor type is pivotal for ideal system performance and efficiency. When choosing between a standard circulation motor, ECM, or variable speed unit, consider these crucial factors:

- Energy consumption ratings and operational costs

- Airflow requirements for your specific home layout

- Compatibility with existing HVAC components

- Climate conditions and seasonal demands in your region

Installation Tips Every Homeowner Should Know

Proper installation of a replacement furnace blower motor requires careful attention to technical specifications and safety protocols.

When upgrading to a PSC or direct drive motor, guarantee proper mounting bracket alignment and secure wiring connections. Consider the motor’s efficiency rating and compatibility with your existing system.

Follow manufacturer guidelines for proper belt tension and pulley alignment to prevent premature wear and maintain ideal performance.

Weighing Costs vs. Benefits: Upgrade or Repair?

Making an informed decision about furnace blower motor replacement requires careful evaluation of both immediate costs and long-term benefits.

When comparing options like Genteq or GE motors, consider these key factors:

- Initial purchase and installation costs versus repair expenses

- Expected power consumption and monthly energy savings

- Manufacturer warranty length and coverage terms

- The projected lifespan of the new motor compared to repairing the existing unit

Conclusion: Protect Your Home with Proactive Furnace Care

Understanding and addressing furnace blower motor issues remains essential for maintaining efficient home heating systems. Through proper diagnosis, timely repairs, and regular maintenance, homeowners can prevent costly breakdowns and extend equipment life. Whether implementing emergency solutions or considering system upgrades, the key lies in prompt attention to warning signs and adherence to maintenance schedules. This proactive approach guarantees ideal performance and reliable heating throughout the cold season.