Regular furnace maintenance keeps systems quiet and reliable by catching wear early and preventing vibration. Technicians tighten fasteners, lubricate moving parts, clean blower blades, replace clogged filters, and align belts to stop rattles, squeals, and roaring. Inspections safeguard ignition components, reduce overheating, and restore efficient combustion, lowering fuel use and repair risk. Scheduling before cold snaps, especially for units over 10 years old, prevents mid-season failures. Warning signs like persistent noise or short cycling warrant immediate service, and there’s more that can help.

Key things to remember

- Technicians tighten, lubricate, and clean components, reducing vibration-induced noise and preventing wear that leads to failures.

- Filter and vent cleaning prevents overheating and airflow restrictions, protecting motors and heat exchangers from costly damage.

- Targeted inspections catch high-wear issues, belts, blower assemblies, inducer grommets, and igniters before they cause squeals, rattles, or breakdowns.

- Securing panels and fasteners and balancing blower blades eliminates rattles, roaring, and startup noises while easing strain on bearings.

- Seasonal tune-ups restore combustion and airflow efficiency, lowering fuel use, reducing mid-season failures, and extending furnace lifespan.

How Furnace Care Prevents Costly Noises and Breakdowns

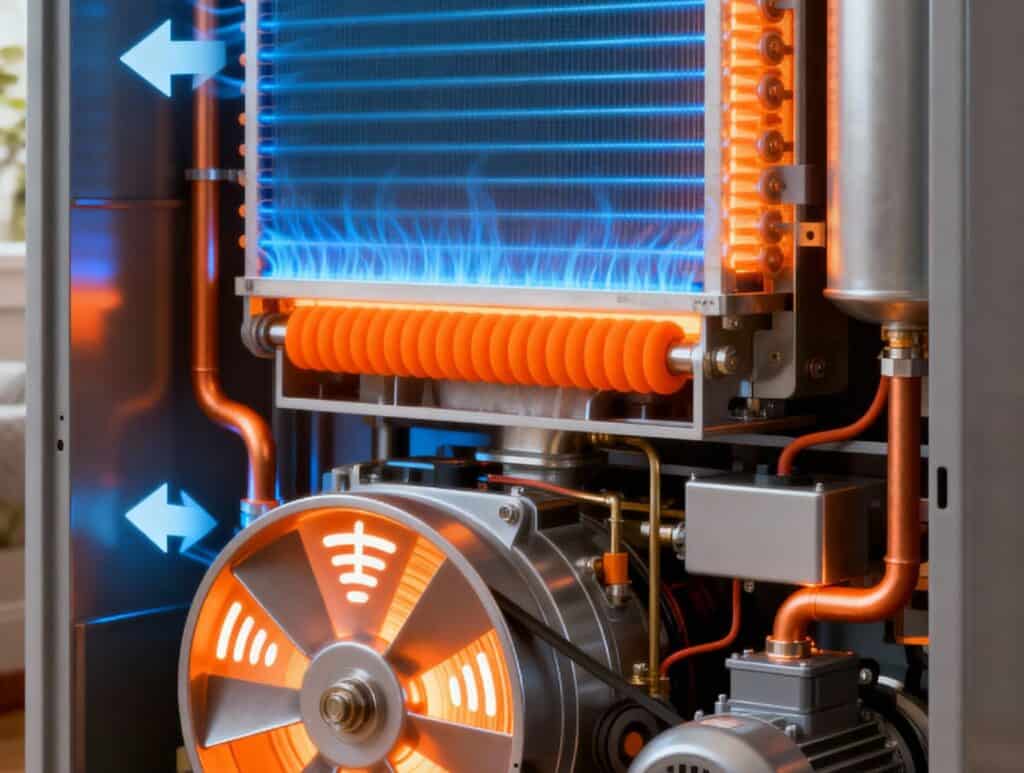

Catching small faults early keeps furnaces quiet and reliable. Regular maintenance targets the wear points that generate noise and drive failures, delivering clear furnace tune-up benefits.

Technicians tighten fasteners, balance blower wheels, and lubricate motors to reduce vibration, a core tactic in noisy furnace prevention. They also replace clogged filters to restore airflow, preventing overheating that warps components and shortens service life.

Inspections catch cracked belts, failing bearings, and misaligned burners before they escalate. Cleaning burners and heat exchangers stabilizes combustion, improving efficiency and lowering strain on ignition parts.

Verifying gas pressures, safety switches, and venting prevents hard starts, shutdown loops, and carbon monoxide risks. Calibrated thermostats and verified electrical connections curb short cycling. Regular service also addresses the airflow and control issues that trigger short cycling, helping stabilize operation and reduce wear.

The result is fewer surprises, quieter operation, and lower lifetime repair costs.

Why Maintenance Matters for a Quieter Furnace

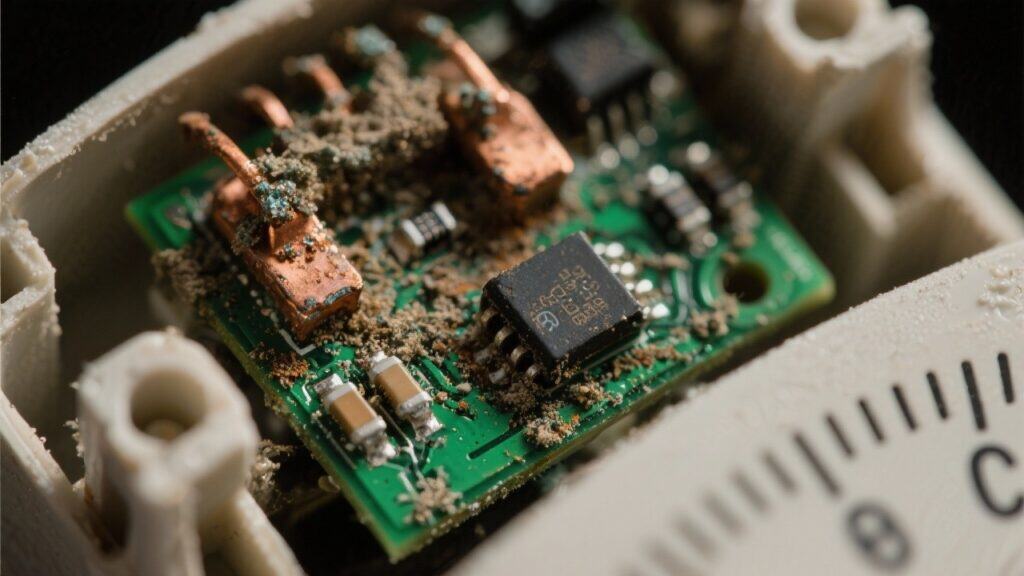

A noisy furnace often signals neglected maintenance, as dust buildup and loose hardware amplify vibration and rattle.

Components most susceptible include blower motors, fan belts, bearings, and panel fasteners, which wear and loosen under continuous operation.

Regular inspection, tightening, lubrication, and filter changes reduce noise by stabilizing these parts and minimizing vibration.

Seasonal tune-ups help prevent startup noises, rattling, and ignition issues before they cause system damage by addressing issues proactively through preventive inspection and adjustments.

The link between noise and neglect

Too often, furnace noise is the first audible symptom of neglected maintenance. Rattles, hums, and booms typically trace back to dirt buildup, loose fasteners, or imbalanced blowers. A basic HVAC repair checklist is designed to catch early. When service is deferred, friction increases, components drift out of alignment, and minor vibrations amplify into disruptive sounds and higher repair risks.

A significant source of unwanted furnace noise and energy loss comes from unnoticed ductwork leaks. When air escapes through gaps in the duct system, the furnace is forced to work harder, increasing vibration, airflow turbulence, and overall system strain.

A defined furnace inspection schedule curbs this escalation by restoring airflow, tightening hardware, and recalibrating performance before wear accelerates.

| Neglect Pattern | Typical Audible Cue |

|---|---|

| Skipped filter changes | Whistling, strained whoosh |

| Infrequent cleaning | Low rumble, burner pop |

| Missed seasonal tune-up | Metallic rattle at startup |

In practice, quieter operation signals that maintenance tasks are timely, measurable, and prevent costlier failures.

Components most affected by wear and vibration

Quiet depends on how well high-wear parts resist vibration and imbalance. The blower assembly leads the list: dry bearings, bent fan blades, and loose set screws cause rattles and airflow losses. Regular blower motor lubrication and impeller cleaning reduce friction, heat, and noise.

Next, inducer motors and their mounting grommets transmit resonance when cushions harden.

Proper care and inspection of heat exchangers are essential for safe, quiet, and efficient operation. A compromised or dirty heat exchanger can cause combustion instability, loud startup noises, and reduced heating performance over time.

Igniters and flame sensors suffer micro-cracking and soot, creating harsh cycling sounds.

Belt-driven systems add pulley misalignment and belt glazing as squeal sources. Heat exchanger expansion noise grows when soot insulates metal. Fasteners on panels, gas valves, and control boards loosen under pulse vibrations.

Practical furnace efficiency tips include: balance the blower wheel, tighten mounts, replace worn grommets, clean sensors, align pulleys, and verify motor amperage against the nameplate.

Key Maintenance Tasks That Prevent Furnace Noise

Preventing furnace noise often begins with cleaning and tightening interior parts that can loosen or collect debris.

Attention to the ignition system and burners helps eliminate clicks, pops, and rumbling caused by misfires or uneven combustion.

Together, these tasks stabilize operation and reduce disruptive sounds.

A dirty or faulty flame sensor can cause ignition misfires and repeated clicking, so cleaning or replacing the flame sensor restores reliable lighting and reduces noise.

Cleaning and tightening interior parts

Targeted cleaning and precise tightening of interior furnace parts directly curb nuisance noises while protecting components from accelerated wear. A disciplined sweep of blower blades, set screws, fan housing, and panel fasteners eliminates vibration points and scraping. As winter furnace preparation intensifies, technicians secure motor mounts, align pulleys, and re-seat access panels to stop rattles before they propagate through ductwork. Pairing this with a professional duct cleaning service reduces debris that can unbalance the blower and hum through supply runs.

| Task | Noise/Failure Prevention |

|---|---|

| Tighten blower wheel set screw | Stops metallic chirps and wobble |

| Clean blower blades and housing | Prevents imbalance and roaring |

| Secure panel fasteners and brackets | Eliminates rattles and buzz |

| Align belt/pulley (if applicable) | Reduces squeal and bearing strain |

Consistent torque checks preserve bearings and reduce costly callbacks.

Checking ignition and burners

Among the most consequential noise sources in a furnace are ignition and burner issues, which often manifest as pops, booms, or rumbling at startup. Proper inspection targets delayed ignition, dirty burners, and weak spark or hot surface igniters.

A technician verifies gas pressure, cleans burner ports, inspects flame sensors for oxidation, and confirms flame color: steady blue with minimal yellow tipping. The igniter’s resistance is checked and wiring connections tightened to guarantee reliable light-off.

Burner alignment and combustion air supply are confirmed to prevent hard starts and resonance. Safety controls are tested for proper shutdown. Documented adjustments support energy-saving HVAC care by restoring efficient combustion, stabilizing startup, reducing stress on the heat exchanger, and eliminating noise that signals impending failures.

How a Seasonal Furnace Tune-Up Saves You Money and Stress

While winter demands push a furnace to its limits, a seasonal tune-up trims costs and worry by keeping the system efficient, safe, and reliable.

A technician cleans burners, calibrates controls, verifies gas pressure, tests safety switches, and replaces clogged filters. These steps restore peak combustion and airflow, reducing fuel use and preventing heat loss.

Tightened electrical connections and lubricated motors cut wear, lowering the chance of mid-season failures and emergency calls. Verifying the heat exchanger and venting reduces carbon monoxide risks, protecting occupants and property. During maintenance, technicians also confirm that the furnace safety switch operates correctly, preventing malfunctions that could shut the system down or compromise safety.

- Relief from surprise breakdowns during freezing nights

- Confidence that energy bills won’t spike unpredictably

- Comfort in steady, quiet heat throughout the home

- Security, knowing safety checks, guards against hazards

- Satisfaction from extending the furnace’s lifespan and value

When to Schedule Professional Maintenance Before Winter

Ideally, professional furnace maintenance should be scheduled in early fall—September to early October, before sustained cold weather drives peak demand. Booking then secures convenient appointment times, allows for parts ordering if issues are found, and guarantees the system is ready when the first cold snap arrives.

Certain homes warrant earlier service. Units older than 10 years, systems with a history of repairs, oil furnaces, or homes with occupants sensitive to air quality should target late August to early September.

After major renovations or an extended vacancy, earlier inspection is prudent.

If early-fall windows are missed, aim for shoulder periods late October or early November while avoiding the season’s first freeze.

Homeowners should also schedule immediately if warning signs appear: persistent noises, short cycling, weak airflow, or rising utility bills.

During scheduling, ask technicians to check for airflow restrictions like dirty filters or blocked returns, as reducing airflow restrictions can boost furnace efficiency and prevent noisy, inefficient operation.

Frequently Asked Questions

Does Furnace Maintenance Affect Home Insurance or Warranty Coverage?

Like a stitch in time, documentation can save nine. Yes, regular furnace maintenance can influence both home insurance and warranty coverage.

Insurers may reward documented upkeep with fewer claim disputes after damage linked to the HVAC. Manufacturer warranties commonly require annual service and filter changes to remain valid, and extended warranties often demand proof.

Neglect, improper installation, or unlicensed work can void coverage. Keep dated invoices, technician reports, and filter logs as evidence.

Are DIY Smart Thermostats Compatible After Professional Furnace Tuning?

Yes. Most DIY smart thermostats remain compatible after professional furnace tuning, provided wiring, voltage, and control stages match the system.

Technicians typically calibrate equipment but do not alter thermostat compatibility. Homeowners should verify: furnace control type (single/two-stage or modulating), common (C) wire availability, high-voltage vs low-voltage, heat pump or dual-fuel settings, and manufacturer advisories.

After tuning, they should rerun the thermostat setup, confirm safety lockouts, and update firmware to guarantee seamless integration.

How Does Humidity Control Interplay With Furnace Noise Issues?

Like a ship battling fog, humidity quietly steers furnace acoustics. High indoor moisture swells ducts and dampers, provoking pops, rattles, and resonance; condensate can also spur blower imbalance and bearing squeal.

Low humidity dries seals and duct joints, inviting whistling air leaks and tinny pinging from thermal expansion. Proper humidification (30–50%), sealed ductwork, balanced airflow, and correct fan speed temper sound, while dehumidification near equipment prevents condensate-born vibration and microbial odour that amplifies perceived noise.

Can Maintenance Reduce Carbon Monoxide Risks From Older Furnaces?

Yes. Regular maintenance reduces carbon monoxide risks in older furnaces by catching cracked heat exchangers, blocked flues, misaligned burners, and incomplete combustion.

A technician inspects combustion seals, tests CO levels, verifies draft and venting, cleans burners, adjusts gas pressure, and confirms safety controls and flame sensors function properly.

Replacing clogged filters and ensuring adequate airflow prevent overheating. They also recommend installing low-level CO detectors and addressing any red-tag conditions promptly to protect occupants.

What Maintenance Records Should I Keep for Home Resale Value?

They should keep a dated log of service visits, itemized invoices, technician reports, parts replaced, filter change schedule, warranty documents, model/serial numbers, permit/inspection approvals, and any efficiency test results.

Include CO detector test dates, flue/vent cleaning records, and thermostat or control upgrades.

Attach photos of major repairs and before/after conditions.

Store manuals and maintenance contracts.

A tidy, chronological packet demonstrates care, supports disclosures, and can justify pricing during home resale negotiations.

Reliable Heating Support for GTA Homeowners: ALP Heating

Homeowners across Vaughan and the GTA rely on ALP Heating for expert furnace diagnostics, efficient repairs, and high-standard HVAC workmanship.

Founded in 2019, the company has quickly risen to prominence, earning multiple HomeStars awards and hundreds of five-star reviews for its consistent service quality.

ALP Heating’s TSSA-licensed team provides fast, dependable help whether it’s fixing a failing furnace, installing new heating equipment, maintaining ductwork, or upgrading to modern smart thermostats.

Their family-driven approach, commitment to safety, and strong community presence make them a trusted choice for both residential and commercial clients in the region.